We worked 6 hours today and made some good visible progress!

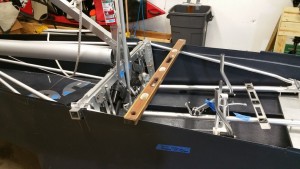

Spent a lot of time with levels trying to make sure the frame was the same height on both sides.

Drilled stringer holes to attach hull using a right angle air drill.

Space is pretty tight, good luck using a normal drill!

We made plastic spacers to fit between the stringers and channel brackets out of UHMW plastic

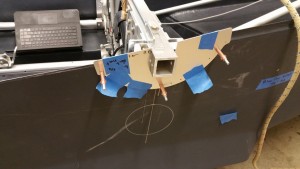

Suspended from the ceiling – first flight

First use of clecoes. It ain’t an RV. Sometimes we use the deburring tool.

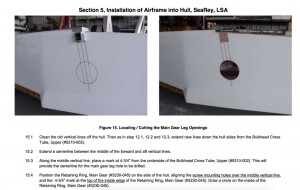

Directions on how to measure and cut the gear leg openings

marking the gear leg holes, 4.75″ below the bar

Here’s the air saw we used.

I get to do the scary “you just wrecked the hull” cut!

Used the vacuum as carbon fiber dust is not good to breathe

Here’s why you want to make sure to regularly inspect the boots for the gear and elevator. Your plane can sink while it is tied up to a dock

Who needs paper manuals? We’re building a laptop holder.