Here’s the ADS-B UAT antenna.

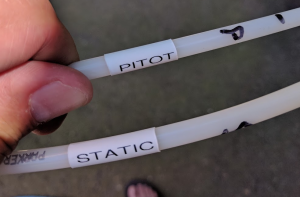

Ran a bunch of wires and hoses for current and future stuff.

Lights, Angle of Attack, Pitot/Static hoses, ADS-B, electrical for strut mounted cameras, etc.

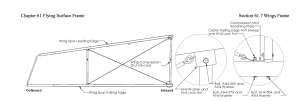

This is a bolt that you don’t want to remove. The anti-sweep cable is attached to that bolt inside the wing and it is under a fair amount of tension. You’ll hear a sproing sound and you’ll have trouble getting that cable reattached without removing the fabric.

Here’s a picture, that bolt is holding the trailing edge anti-sweep cable.

Polished the aileron torque tubes and lubricated the blocks.

I spent a couple of hours modifying our wing cart to both make it shorter, and so that it would fit in a 26 foot u-haul truck because it was initially to tall. I also put full 2×4 side boards on it to help tie the cart to the truck walls and to protect it during transport.

Then next week we transported the wings to get covered by an A&P who gave us a good rate. I didn’t want to use the chemical stuff in my garage – although we both took the EAA Fabric covering class so we have an idea about what we were missing out on. 🙂 Several people have told us that fabric covering is their favorite part of the build so I wouldn’t discourage others from doing it themselves. The FAA does allow you to hire out the fabric covering and still meet the 51% built by amateurs for Searey kits.