We took our rudder pedals apart to replace the defective rudder control blocks. They were not made with enough material and several people have reported that the center block is cracking and failing during taxi or flight. Then the rudder controls don’t work properly. Not catastrophic but still dangerous.

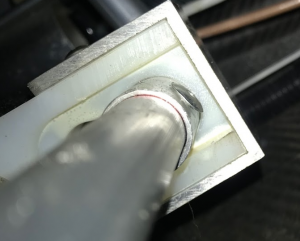

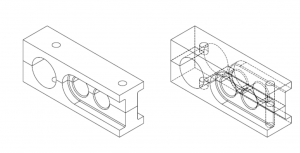

Here’s a picture comparing the old and new one. You might wonder why the part has that u-shaped depression cut out of it? That’s because the rudder pedal assembly comes as a solid piece and you have to slide that block around some 90 degree bends. It won’t get around the curved right angle rudder assembly corner without that groove. You also need some clearance for the riveted collar on the rudder assembly.

People are either replacing them with the longer part or strengthening the shorter part with pipe hanger or aluminum channel brackets as shown. It is really difficult to replace the blocks in a completed plane so it makes sense to strengthen them for safety. Both solutions should work well. We’re now planning on getting a new aluminum part and returning the other blocks.

The old blocks wouldn’t come off until we removed the rudder pedals. Drilling out those rivets messed up the rudder pedal assembly parts 2720-008 so we ordered new ones for $88. That rudder pedal assembly is a solid piece of aluminum. The directions are unclear but it seemed like they wanted you to use short rivets that would lodge inside the aluminum. I opted to order longer rivets that would go all the way through the through the rudder assembly and pedal. I chose stainless steel which is really hard to drill out. We’re thinking about leaving the pedals off now – partly because they are pretty expensive and we don’t want to purchase them twice. We don’t want the ugly holes in the rudder assembly tubes so we’re going to replace those.

Here’s what a smart Searey pilot told me: “I have mixed feelings about the rudder pedals. They look nice, give additional support for your feet but are a pain to get around if you’re doing any work in the nose. I don’t rivet mine on, I drill completely through and bolt / nut them with 8/32 screws so they can be removed if need be.”

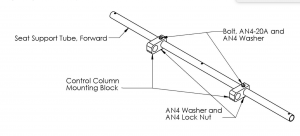

I’m also looking cross-eyed at the control column mounting block part #2720-004. It looks too thin on the front side.

This thing failing would be a much bigger deal than losing the rudder block while flying.

I believe that these blocks are made out of a plastic called UHMW – Ultra High Molecular Weight Polyethylene.

It’s good stuff but it gets brittle as it ages.

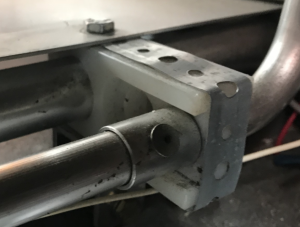

Update: One of the Searey pilots has designed some new control column mounting block parts that are two piece aluminum. He was generous enough to offer to sell us a pair of those. Here’s what they look like on my kitchen counter:

He is also going to make two piece aluminum rudder control blocks which we are looking forward to!

On to a different topic, Bilge Pumps.

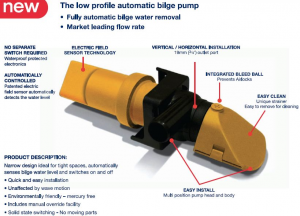

Next we mounted the two bilge pumps in the hull. We chose the Whale Supersub SS5212 bilge pumps. They are low profile and will theoretically pump out more water than other brands. Other Searey owners have had good experience with them.

We’re putting one in the step and one in the tail. There are a lot of opinions about if you need one pump or two, we decided on two after reading all the stuff on the private Searey forum.

Here is a picture of how both pumps are placed.

Here’s how the rear pump will be placed. It isn’t easily accessible once the plane is done.

The pump in the step goes on the bilge pump service mount plate (5330-019). It’s really just a plastic strip so that you can pull it back to the bulkhead to service it if it breaks. It attaches to the hull with two #8 x1/2″ sheet metal screws. That plastic strip costs $25 from Searey but any flexible plastic that is 23″ long by 2″ wide would work.