We worked on building the wing frames this weekend. We also sprayed CorrosionX in the wing tubes. Things of note:

Putting the wing tip on using superglue to attach the washer to the nut so that you can hold both of them inside the tube with a needle nose pliers. – Or you could just get a flanged nut.

Debur the holes that you drill in the spars. The anti sweep cables may be hard to stretch to attach. You can lengthen or shorten them by twisting them. You may have to file the plywood wing ribs to get them to fit properly. Some of the 50 inch pound torque specs are too much, will deform the smaller wing tip tubes.

Wing spars

I didn’t deform that tube

You have to twist the cables to shorten or lengthen them.

Not too heavy!

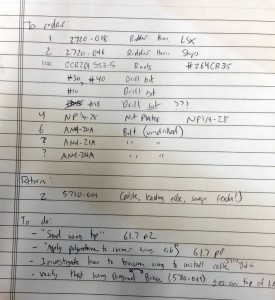

Stuff to order for next time

Another new pulley

New aluminum pulley vs. phenolic rubber

Nicer to build the wings on sawhorses

Wing tip tube

We have two wings now. It was warm enough outside to build with the doors open which isn’t right for Christmas in Wisconsin.