We worked on the lower wing ribs today. First Ethan helped me fix my snowblower!

The clutch mechanism wasn’t engaging fully.

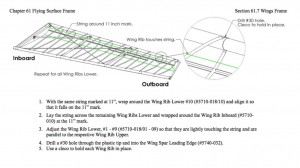

Here are the lower wing ribs laid out

Here’s how they attach. On a prior page it says to “align the plastic tip to fit the radius of the wing spar leading edge.

If you do that the trailing edge doesn’t fit the radius exactly but the rivet will pull it in and create a little more bow in the rib.

That’s how we did it. It seems most important for all the ribs to be the same height – just touching the string so that they

don’t appear at different heights looking bad when the fabric is on.

Controversial line to try to get the first lower wing rib right above the upper wing rib.

Since Ethan drew it, I’m calling it an 87.2 degree angle, Ethan says 90 degrees. It’s just a wing, close enough!

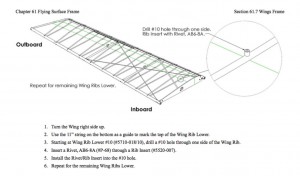

First wing rib support insert is 11 inches from the leading spar edge

Inserts are drilled in every rib on the top and bottom. They’ll hold the ten Wing Rib Supports.

Here are some inserts installed. #10 drill bit, rivet, and rib insert.

This little John Menard memorial punch helps make a starting mark for the drill bit on the narrow tubes.

Riveting the tubes. Two of the rivets mandrel heads pulled through vs. snapping off. We think that was because the regulator pressure

on the compressor was set too high. The regulator on my compressor is broken so we have not been adjusting it. I ordered a regulator rebuild kit.

We think we may need to purchase 2 new lower ribs as the hole seems too big when we drilled out the rivet.

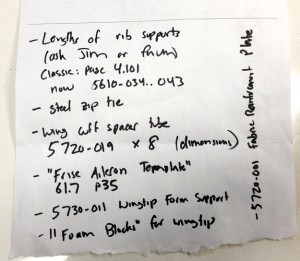

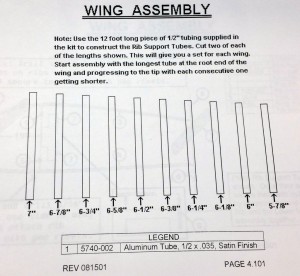

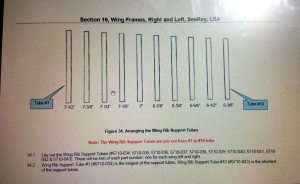

Today’s task – figure out how long the wing rib supports need to be because we need to cut them from a tube supplied

in our original kit. You can buy them pre-cut but you might do better making them yourself.

Tips from Jim Ratte:

Put a upper / lower rib in place with Clecos on the spar and measuring the distance between. If its close, I would attach the inboard set of ribs, outboard set of ribs, then run a string along the top of the ribs. Set the other ribs in place (the string will make sure the rib heights are all in-line with each other) and after the remaining ribs are in measure the distance for the other tubes to cut.

Don’t make the rib supports so tight that you are spreading the ribs apart further. The stainless tie wraps will go over the ribs to secure them in place where the tubes are.

Classic wing rib support lengths

LSX wing rib support lengths – new wing airfoil is 1/2 inch deeper than the Classic wing.

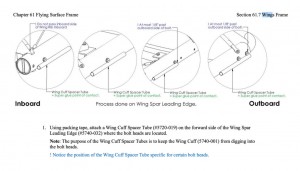

We’ll also make the Wing Cuff spacer tubes as we don’t have those. They are just half inch tubes, cut 4-6 inches in length.

The wing is getting progressively heavier to lift.