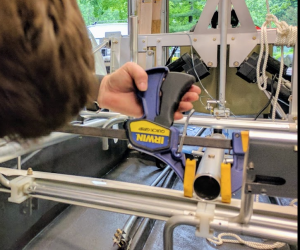

We noticed that if you put the recommended torque of 60-70 inch lbs on the fuselage tube bolts, that they start to deform.

We used a clamp to make them round again and created some anti compression sleeves for the bolts so that we could torque them.

We did this with plastic tubes.

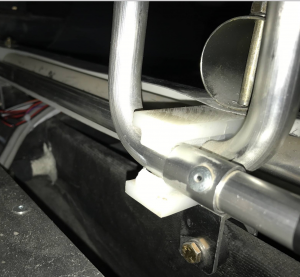

We should have changed out the defective rudder pedal control blocks when we did this but we didn’t have the new ones yet.

Here’s a picture of a rudder pedal control block that broke while flying. The “new” part that inexplicably has the same part number has an extra 3/4 inch of plastic vs. the 1/8 inch on our current parts. 2720-003 is the part number for both the defective and improved parts.

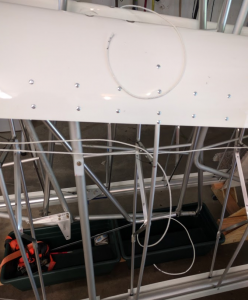

We also ran some electrical wire for lights and sensors in the wings and put on some zip ties to hold them.

One zip tie around the wire and another going thru to hold it to the rib support tube.

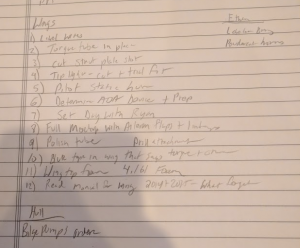

list of to-do items for next time.