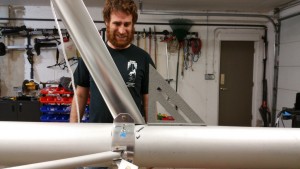

Today we did a trial fitting of the fuel tank. We also riveted the cluster bracket which had been waiting for a while.

On day 2 we sprayed the inside of the fuselage tubes with CorrosionX protectant.

I brought up the turtledeck and we tried it on the hull

Here’s a pic of the gas tank strapped in with the fuel tank angle forward and back supports.

I told Ethan the airsaw would cut this fuel tank angle forward better than the dremel cutoff attachment did.

We installed angle brackets on both sides, front and back.

We had originally installed the cluster bracket upside down (pre-Ethan) and drilled holes in the wrong places so now we had to finish correcting that situation by drilling some new holes and putting in some new rivets. The fuselage frame flexed at this point without the rivets and we needed to stiffen everything up before riveting in the fuel tank angles because the flexing affected their positioning.. We spent some time adjusting things so the cluster bracket was perpindicular to the boom tube. It would twist slightly before it was riveted, we wanted it to be perpindicular to the boom tube.

Blue tape covering the incorrect hole we drilled.

Here’s a picture of a boom tube that had too hard of a landing. We’ll need to inspect the boom tube periodically. We’ve got a remote camera that should help.

Here’s the sprayer we used to coat the inside of the tubes. It worked pretty well, good atomization of the fluid.

On some of the long tubes we put a shop vac on the other side to help draw the spray throughout the tube.